Electrical Audit

Electrical Audit

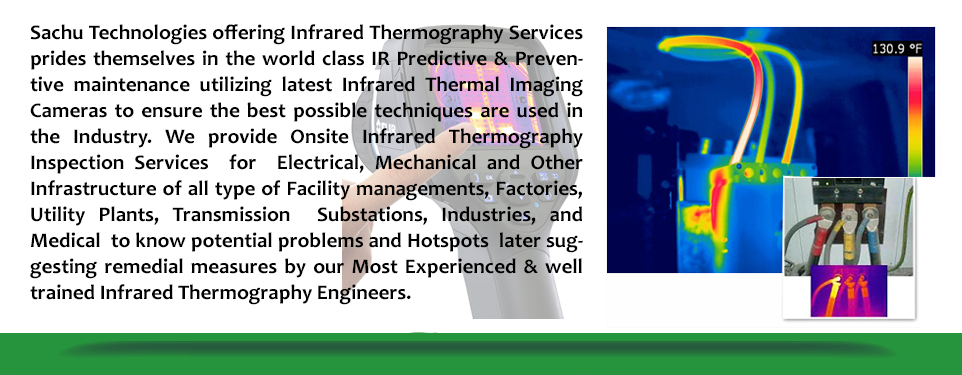

Sachu Technologies offering Electrical Safety Audit to avoid Electrical hazards continue to threaten safety of people and property in the form of shocks, burns, injury, fire and explosion. With electricity having become an indispensable part of our life, electrical risks are to be managed effectively. In process industries, Plants fires due to electrical reasons are very probable, especially in industries that handle flammable chemicals. In service industries such as Software companies, information technology, telecommunications, banking and other commercial establishments, business interruption losses due to electrical hazards (fire in server room, damage of expensive communication equipment, loss of data, fire in cable gallery, etc.) could be substantial.

|

Typical scope of Electrical Safety study

Methodology

Electrical Audit consists of Studying, Assessing, Measuring and Analyzing electrical utilities. In a typical Plant the electrical utilities consists of

Electrical Safety Audit has become crucial to the proper maintenance of the Facility .Electrical Safety Audit is conducted to investigate if complaints and concerns by workers regarding electrical safety is substantiated and if there are other electrical safety or general safety hazards at the facility that should be addressed. The audit focus on current electrical safety conditions, and selected other safety measures for the facility. The Electrical Audit report mainly consists of detailed analysis of the measurements, tables, pictures, graphical depictions and important calculations. Energy saving recommendations are also included in the Report .