Power Factory Study

Power Factory Study

Power Factor Study in India –Sachu Technologies

Sachu Technologies offer Power Factor Study after analyzing consumer power factor in last 12 month billing cycle. The study is carried out at Mains (Upstream) and at various Load Points (Downstream).

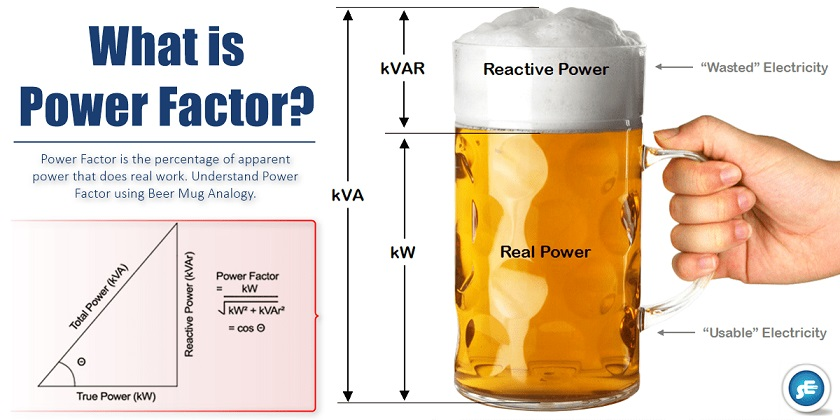

Power Factor is ratio of the actual electrical power dissipated by an AC circuit to the product of the r.m.s. values of current and voltage. The difference between the two is caused by reactance in the circuit and represents power that does no useful work.

|

It shall help in following way

Displacement Power Factor

The displacement power factor is the power factor due to the phase shift between voltage and current at the fundamental line frequency. For sinusoidal (non-distorted) currents, the displacement power factor is the same as the apparent power factor.Inductive loads cause current to lag behind voltage, while capacitive loads cause current to lead voltage

Why Perform Power Factor Testing?

Most failures of electrical equipment are the result of a breakdown in the insulation system. Power factor testing is an effective way to detect defective electrical equipment insulation. Power factor is the ratio of the capacitive or ‘charging’ current (measured in voltamperes) to resistive or ‘leakage’ current (measured in watts). It is a means of measuring insulation integrity since the smaller the power factor, the better the insulator. Insulation may be deteriorating, however, the equipment may not fail for some time. Although this condition represents a serious hazard, if deteriorated insulation is detected before failure, it can often be reconditioned instead of being replaced. This allows corrective action to be taken during a planned outage before extensive equipment damage results from insulation failure. Power factor testing also makes it possible to detect equipment insulation problems without making an internal visual inspection. The result is a significant decrease in maintenance cost and downtime. Power factor testing is one of the best testing techniques for predictive and preventive maintenance

A power factor study is a key to properly determining a system’s power factor correction requirements. A study determines capacitor size and location as well as the number of steps and incremental sizes to be switched. A study also provides an economic analysis of the proposed installation based on the forecast reduction in electric utility bills. A power factor study can be divided into three major steps.

Review of the electric utility company’s rate structure.

Development of a graphical profile of the facilities kVA, kW and kvar.

Determination of the required capacitor kvar additions for the desired power factor improvement level.

The power factor study begins with a utility rate structure review together with a historical sample (six to 24 months) of electric bills. This information is used to evaluate present use patterns and to determine the potential economic benefits of improving power factor. Utility rate structures usually provide significant economic incentives to reduce total kVA demand. The taken data is used to develop the graphical profile which is plotted with respect to time to provide a representation of a complete operating cycle. This profile can then be used to determine the required kvar of capacitors necessary and the number of Switching steps to offset the inductive kvar.The minimum reactive kvar determine the amount of capacitors that can be used without switching to provide close to 100 percent power factor during minimum load conditions. Additional capacitor requirements can be determined based on the profile and sized as needed. Capacitance is introduced into the facilities electrical distribution system to balance inductance due to equipment operation. When equipment load, and subsequently inductance decreases, capacitance also should be reduced. For more erratic demand patters, more switching steps may be required.