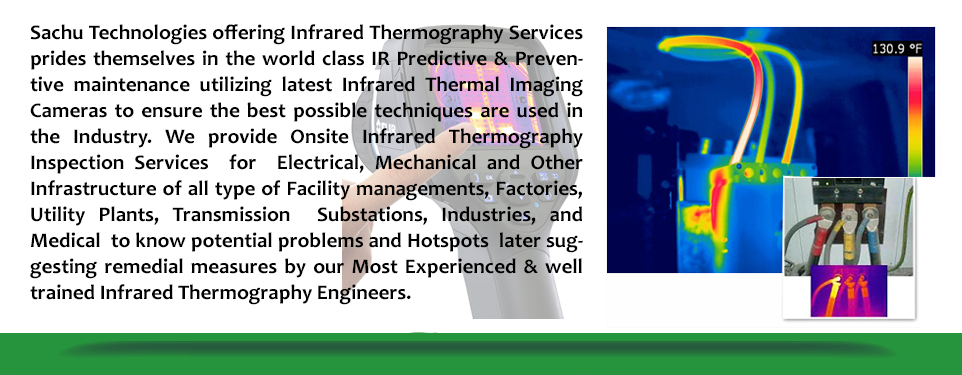

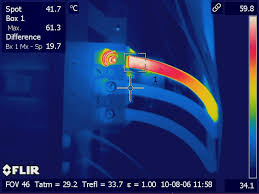

Sachu Technologies offers Thermography Services and Thermal Imaging Solutions in India using Infrared Cameras with a 160 x 120 and 320 x 240 pixels resolution deliver superior image quality. Infrared thermography is Scientific Camera which detects infrared energy emitted from object converts it to temperature, and displays image of temperature distribution.Infrared thermography is the art of transforming an infrared image into a radiometric one, which allows temperature values to be read from the image.

A small electrical problem can have extremely far-reaching consequences.

The efficiency of the electrical grid becomes low, and so the energy is spent generating heat.

If left unchecked, heat can rise to the point where connections start to melt. Not only that, but

sparks can fly that might start a fire. Infrared Thermal Imaging Camera solves through Scan, visualize and

analyze temperatures of Electrical Mechanical, Building , Refractory systems quickly and accurately. Infrared energy

coming from an object is focused by the optics onto an infrared detector . The detector sends the information to sensor electronics for image processing. The electronics translate the data coming from the detector into an image that can be viewed in the viewfinder or on LCD screen

Our company arranges Interchangeable Tele photo and Wide angle lenses can help you to adapt our thermal imaging camera to every

situation distant targets to do Thermovision Hot spot Scanning such as, Transmission line Towers and overhead power lines.

We can provide the most advanced thermal imaging solutions to support 24/7 monitoring programs that keep the vital electrical

power grid up and running.

Thermal imaging cameras are commonly used for inspections of Electrical,Mechanical systems, Pipe work Faults , Refractory and petrochemical installations and components in all sizes and shapes Examples of failures in systems that can be detected with thermal imaging:

Thermography

Thermography